The Complete Guide to Fudge Boxes Packaging Sweet Success

Fudge is more than just a sweet treat in the UK; it is a tradition. From the crumbly, buttery tablets of Scotland to the smooth, clotted cream varieties found in seaside towns like Cornwall and Devon, fudge holds a special place in the British heart. For confectioners, however, the challenge lies not just in perfecting the recipe but in presenting the final product. The right packaging is essential for maintaining freshness, attracting customers, and elevating the perceived value of your confectionery.

This comprehensive guide delves into the world of packaging for fudge. We will explore why specialized boxes matter, how to choose the right materials, the importance of branding, and how to source the best options for your business.

Why Specialized Packaging Matters for Fudge

Fudge is a delicate confection. It is sensitive to temperature and humidity, and depending on the recipe, it can either dry out and become rock hard or absorb moisture and become sticky. Standard food containers often lack the specific properties needed to keep fudge at its best.

Specialized containers are designed to address these issues. They often feature grease-resistant linings to prevent butter or cream from staining the card, which looks unsightly and can compromise the box’s structure. Furthermore, they provide a snug fit. Unlike biscuits or hard candies, fudge can be heavy and dense. If it rattles around in a box that is too large, it can become misshapen or damaged. A well-designed box keeps the product secure, ensuring that the customer experiences the texture exactly as the maker intended.

Beyond protection, presentation is key. In a market saturated with artisanal sweets, your product needs to stand out on the shelf. A premium box suggests a premium product. It tells the customer that care has been taken at every stage, from the pot to the packaging.

Choosing the Perfect Material

When selecting fudge boxes, the material is your first major decision. In the UK market, there is a strong preference for packaging that balances aesthetic appeal with environmental responsibility.

Folding Box Board (FBB):

This is the industry standard for lightweight confectionery. It offers a smooth surface that is excellent for high-quality printing, making it ideal if your brand relies on vibrant colours or intricate designs. It is cost-effective and comes flat-packed, saving valuable storage space in small kitchens or shops.

Rigid Board:

For luxury lines, rigid board is the superior choice. It is thick, sturdy, and offers a substantial feel in the hand. These boxes do not require assembly and provide excellent protection for heavier slabs of fudge. They often feature magnetic closures or separate lids, adding to the “gift” experience.

Kraft Paper:

Natural Kraft paper is increasingly popular for artisan brands. Its unbleached, rustic appearance hints at homemade, natural ingredients. It appeals to eco-conscious consumers and pairs beautifully with simple accessories like jute twine or a stamped logo.

Window Patches:

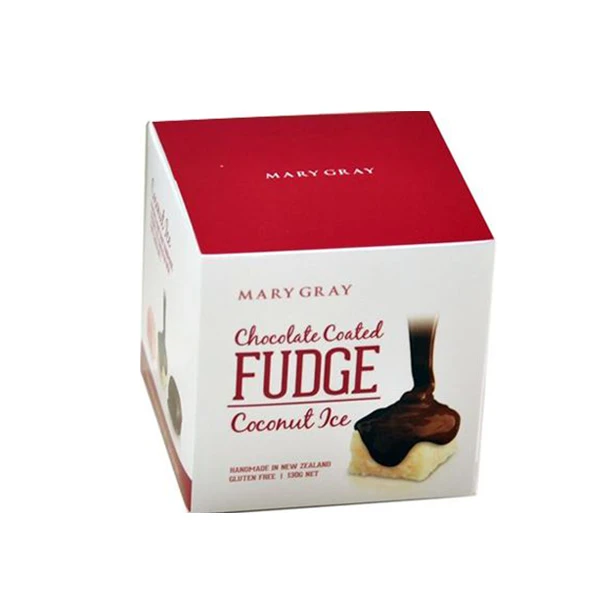

Many confectioners opt for fudge boxes packaging that includes a transparent window. This allows the product to sell itself. When customers can see the marble effect of a chocolate swirl or the chunks of walnut in a maple fudge, the temptation is immediate. These windows are typically made from food-safe plastics or biodegradable PLA films.

The Art of Presentation and Gifting

Fudge is frequently purchased as a gift, whether as a souvenir from a holiday, a thank-you gesture, or a stocking filler at Christmas. Consequently, your packaging needs to transition seamlessly from a retail item to a present.

Fudge gift boxes are designed with this specific purpose in mind. They often feature higher-quality finishes, such as gold or silver foil blocking, spot UV varnish to highlight logos, or textured papers. The internal presentation is just as important. Many gift-style boxes include dividers to separate different flavours, preventing flavour migration and keeping the arrangement neat.

Consider the “unboxing” experience. Tissue paper linings, branded stickers, or a small card detailing the history of your fudge recipe can add significant value. These small touches turn a simple transaction into a memorable experience, encouraging repeat business and word-of-mouth recommendations.

Sourcing Your Packaging

For UK businesses, sourcing packaging requires balancing cost, quality, and logistics. The temptation for many start-ups is to search for fudge boxes near me in hopes of finding a local cash-and-carry. While this can be useful for immediate, last-minute needs, it rarely offers the best price or variety.

Local retail outlets often stock generic sizes that may not fit your specific slab or cube dimensions perfectly. This leads to the need for extra padding or cutting your product to fit the box, neither of which is efficient.

For scalability and consistency, specialized packaging suppliers are the better route. They can offer a wider range of specific dimensions tailored to standard fudge cuts. When you are ready to scale up production, buying fudge boxes wholesale becomes a necessity. Bulk purchasing significantly reduces the unit cost, improving your profit margins—a critical factor in the food industry where ingredient costs can fluctuate.

A reliable supplier will also understand UK food safety regulations, ensuring that all materials used are food-grade and compliant with current legislation. This peace of mind is invaluable.

Sustainability: A Modern Imperative

The UK consumer is more environmentally aware than ever before. Excessive plastic and non-recyclable materials are increasingly frowned upon. Your packaging is a statement of your brand’s ethics.

Opt for materials that are FSC-certified, ensuring the wood pulp comes from responsibly managed forests. If you use plastic windows, check if they are recyclable or compostable. Clearly labelling your boxes with disposal instructions helps your customers do the right thing and reinforces your brand’s commitment to sustainability.

Furthermore, many businesses are now looking for fudge boxes empty of any plastic linings entirely, relying instead on high-quality greaseproof papers to protect the card. This mono-material approach makes recycling much easier for the end consumer.

Customisation and Branding

In a crowded marketplace, generic packaging is invisible. Customisation is how you build a brand identity.

Your box is your canvas. It should reflect the personality of your fudge. Is it a traditional, old-fashioned recipe? Then classic serif fonts and muted, heritage colours might work best. Is it a modern, experimental brand with crazy flavours? Then bold, bright graphics and quirky copy are the way to go.

Digital printing has made customisation accessible even for smaller runs. You no longer need to order thousands of units to get your logo on a box. However, if full custom printing is out of your budget initially, creative use of labels, sleeves, or stamps on plain stock boxes can achieve a professional look for a fraction of the cost.

Conclusion

Packaging is the final ingredient in your fudge recipe. It protects the quality you have worked hard to achieve and communicates your brand’s story to the customer. Whether you are a small home business selling at weekend markets or a large producer supplying national retailers, the right box makes all the difference.

By partnering with experts like wholesaleboxes.co.uk, you can find the perfect solution that balances protection, presentation, and price. Invest in your packaging, and you invest in the future success of your sweet creations.

Frequently Asked Questions (FAQs)

Do I need to line my fudge boxes?

Yes, it is highly recommended. Fudge has a high butter and sugar content. Without a barrier, the grease can seep into the cardboard, causing unsightly stains on the outside of the box. You can use wax paper, greaseproof paper sheets, or choose boxes that come with a food-safe poly-coating on the inside.

What is the standard size for a fudge box?

There is no single “standard” size as fudge is cut differently by every maker—some prefer cubes, others slabs. However, common retail sizes are designed to hold 150g to 200g of product. It is crucial to measure your specific cut and arrangement before ordering packaging to ensure a snug fit that prevents movement.

Can I use cake boxes for fudge?

Technically yes, but they are often not ideal. Cake boxes are usually designed with more height to accommodate frosting and decorations, which means a layer of fudge might look lost at the bottom. Fudge boxes are typically shallower to showcase the product better. Additionally, cake boxes might not be sturdy enough for the density of fudge.

How do I keep fudge fresh in the box?

Fudge needs to be kept in an airtight environment to prevent it from drying out or becoming sticky. If your box is not airtight (most folding cartons are not), you should wrap the fudge in cellophane or seal it in a food-safe bag before placing it inside the box. Rigid boxes with tight-fitting lids offer better protection but secondary wrapping is still best practice for shelf life.

are window patches on boxes biodegradable?

Not all of them. Traditional window patches are made from petroleum-based plastics which are not biodegradable. However, many modern eco-friendly boxes use PLA (polylactic acid) windows derived from plant starch like corn or sugarcane. These are compostable. Always check the specifications with your supplier if sustainability is a priority for you.